Wood-Plastic Composite (WPC) wall panels have gained immense popularity as a versatile and sustainable alternative to traditional wall paneling materials.

These panels combine the natural aesthetics of wood with the durability and low-maintenance benefits of plastic, making them an attractive choice for both residential and commercial applications.

However, understanding the factors that influence WPC wall panel pricing is essential for consumers and industry professionals alike.

In this essay, we will delve into the various aspects that impact the cost of WPC wall panels, providing valuable insights into the economics of this innovative building material.

I. Raw Materials and Composition

The composition of WPC wall panels plays a crucial role in determining their pricing. WPC panels typically consist of a blend of wood fibers or flour,

thermoplastic polymers (such as polyethylene, polypropylene, or PVC), and additives that enhance the material’s performance.

The quality and proportion of these components directly influence the final product’s cost and performance.

- Wood Fiber Type and Quality: The type and quality of wood fibers used in WPC wall panels significantly affect their price. High-quality wood fibers, obtained from hardwood species, tend to be more expensive than those from softwood species. Additionally, the degree of refinement and treatment of the wood fibers can impact the final panel’s strength, appearance, and resistance to moisture and decay.

- Thermoplastic Polymers: Different types of thermoplastic polymers can be utilized in WPC wall panels, and each comes with its own price and performance characteristics. For instance, polyethylene-based WPC panels are generally more affordable compared to those made from PVC, but the latter offers higher rigidity and better fire resistance.

- Additives and Enhancements: Various additives, such as stabilizers, colorants, and UV inhibitors, may be incorporated into WPC panels to enhance their properties and appearance. The cost of these additives can contribute to the overall price of the panels.

II. Manufacturing Process

The manufacturing process of WPC wall panels also plays a significant role in their pricing.

There are two primary methods of producing WPC panels: extrusion and injection molding.

- Extrusion Process: Extrusion is the most common method for producing WPC wall panels. In this process, the raw materials are mixed and heated before being forced through a die to form the desired shape. The extrusion process is relatively cost-effective and allows for the production of large quantities of panels in a continuous manner.

- Injection Molding Process: Injection molding involves melting the thermoplastic polymer and injecting it into a mold that shapes the WPC panel. This method is generally more expensive and suited for producing smaller quantities or customized designs.

The complexity of the manufacturing process, the quality of equipment, and the expertise of the manufacturer can all influence the production costs, which, in turn, affect the final pricing of the WPC wall panels.

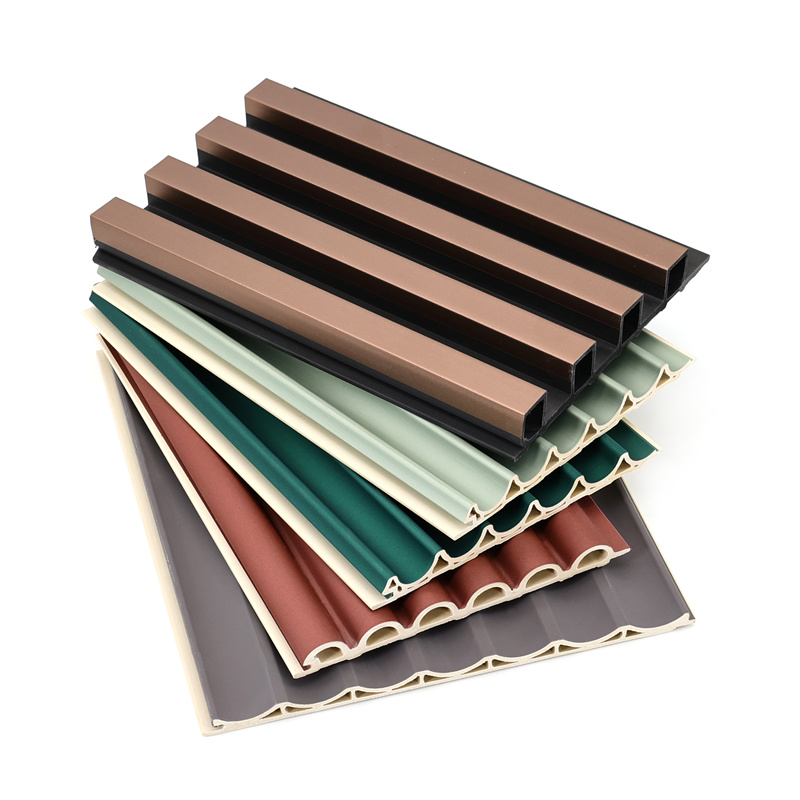

III. Panel Design and Aesthetics

The design and aesthetics of WPC wall panels can range from simple to intricate, and the level of detailing directly impacts the cost.

- Surface Texture and Finish: WPC panels can be produced with various surface textures, such as smooth, embossed, or brushed finishes. More intricate textures often require specialized production techniques, which can increase the price of the panels.

- Color and Pattern: The choice of color and pattern can significantly influence the perceived value of WPC wall panels. Customized colors or complex patterns may require additional processes or involve the use of premium pigments, which can add to the overall cost.

- Size and Thickness: The size and thickness of WPC panels can be tailored to specific project requirements. Larger or thicker panels may necessitate adjustments to the production process, potentially affecting the price.

IV. Certification and Standards

Certification and adherence to industry standards also impact WPC wall panel pricing. Panels that meet recognized quality standards for durability, fire resistance,

and environmental sustainability may have a higher initial cost but can provide long-term benefits and peace of mind to the consumer.

- Safety and Fire Ratings: WPC panels that comply with fire safety regulations and possess higher fire resistance may cost more due to the additional measures taken during production.

- Environmental Certifications: WPC panels certified for their eco-friendliness and sustainability might command a premium price, as consumers increasingly prioritize environmentally responsible products.

Demystifying WPC wall panel pricing involves a comprehensive understanding of the various factors that influence the cost.

The choice of raw materials, the manufacturing process, panel design, and adherence to industry standards all play significant roles in determining the final price of WPC wall panels.

As the demand for eco-friendly and durable building materials grows,

gaining insights into these factors will enable consumers and industry professionals to make informed decisions and strike a balance between quality, aesthetics, and budget when investing in WPC wall panels.