Wood-Plastic Composite (WPC) wall panels have gained significant popularity in the construction and design industries due to their remarkable durability, versatility, and eco-friendly nature.

Understanding the science behind these panels is crucial for both manufacturers and consumers alike.

In this article, we will delve into the composition and performance of WPC wall panels, shedding light on the scientific principles that make them a superior choice.

We will also explore the roles of manufacturers, suppliers, and pricing in the procurement of high-quality WPC wall panels.

I. Composition: Blending Nature and Technology

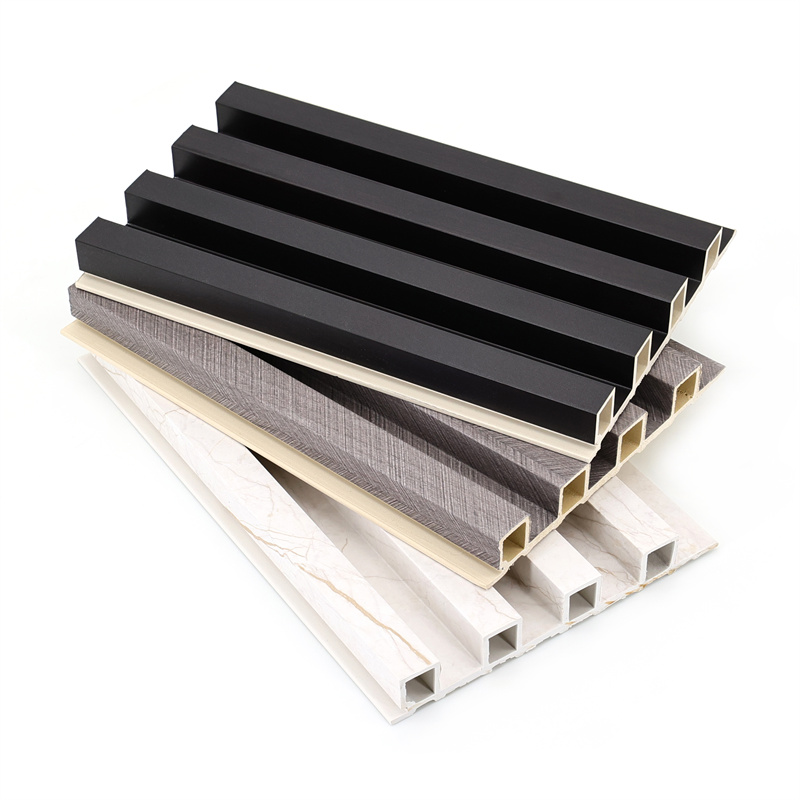

WPC wall panels are crafted by blending wood fibers with thermoplastic polymers, such as polyethylene, polypropylene, or PVC.

Wood fibers provide natural beauty and texture while enhancing the overall strength and stability of the panels.

The type and quality of wood fibers used directly impact the appearance and performance of the panels.

Manufacturers carefully select wood fibers from sustainable sources, ensuring responsible forest management practices.

The choice of thermoplastic polymers in the composition of WPC wall panels plays a vital role in determining their durability and weather resistance.

Polyethylene, polypropylene, or PVC polymers offer excellent resistance against moisture, rot, and fungal growth, making WPC panels suitable for both interior and exterior applications.

These polymers also enhance the panels’ dimensional stability, reducing the risk of warping or cracking.

II. Manufacturing Process: Transforming Materials into WPC Wall Panels

The manufacturing process of WPC wall panels involves an advanced extrusion technique.

In this process, the wood fibers and thermoplastic polymers are thoroughly mixed and heated to form a homogeneous mixture.

The mixture is then forced through a die, which imparts the desired shape and dimensions to the panels.

The extrusion process ensures precise control over panel thickness and consistency, resulting in uniform quality across the production batch.

To further enhance the performance and appearance of WPC wall panels, manufacturers incorporate additives during the manufacturing process.

These additives may include UV stabilizers to protect against sunlight-induced fading, colorants to achieve desired hues, and fire-retardant compounds for improved safety.

Each additive serves a specific purpose, ensuring that the panels meet stringent performance standards and aesthetic requirements.

III. Performance: Unveiling the Strengths of WPC Wall Panels

WPC wall panels are renowned for their exceptional durability.

The combination of wood fibers and thermoplastic polymers creates a panel that can withstand heavy impact, resist scratches, and maintain structural integrity over time.

This durability makes WPC panels an ideal choice for high-traffic areas or spaces prone to wear and tear, such as commercial buildings and public facilities.

One of the key advantages of WPC wall panels is their outstanding weather resistance.

The inherent properties of thermoplastic polymers prevent water absorption, protecting the panels from rot, swelling, or degradation due to moisture.

Additionally, the inclusion of UV stabilizers in the manufacturing process ensures that the panels retain their color and appearance even when exposed to prolonged sunlight.

IV.Procurement and Considerations: Manufacturer, Supplier, and Pricing

Choosing a reputable manufacturer is crucial to ensuring the quality and performance of WPC wall panels.

Look for manufacturers with a proven track record, certifications, and a commitment to innovation.

Reputable manufacturers invest in research and development to improve panel quality, develop new designs, and explore eco-friendly manufacturing practices.

Suppliers play a vital role in connecting manufacturers with consumers.

Partner with suppliers who have a comprehensive network and access to a wide range of WPC wall panels.

Evaluate their reputation, inventory, customer service, and delivery capabilities to ensure a smooth procurement process.

While price is an important factor, it should not be the sole determinant in selecting WPC wall panels.

Consider the quality of raw materials, manufacturing techniques, panel thickness, and additional features when comparing prices.

Striking a balance between affordability and quality ensures that you obtain panels that offer long-term value and meet your specific requirements.

Understanding the science behind WPC wall panels is crucial for manufacturers and consumers alike.

The composition of wood fibers and thermoplastic polymers, coupled with advanced manufacturing processes, results in panels that are durable, weather-resistant, and aesthetically appealing.

By selecting reputable manufacturers and suppliers and considering pricing alongside quality, consumers can procure high-quality WPC wall panels that enhance the durability and aesthetic appeal of their spaces.

With their superior performance, WPC wall panels continue to revolutionize the construction and design industries with a perfect blend of nature and technology.