Wood Plastic Composite (WPC) wall panels have gained significant popularity in the construction and interior design industries due to their eco-friendly nature, versatility, and aesthetic appeal.

As the demand for WPC wall panels continues to rise, so does the importance of understanding the factors that influence their prices.

Among these factors, material quality plays a crucial role in determining the cost of WPC wall panels.

This essay delves into the impact of material quality on WPC wall panel prices, exploring how the choice of materials affects both the manufacturing process and the final product’s performance.

By examining this relationship, consumers and industry professionals can make informed decisions when it comes to selecting WPC wall panels that offer the best value for their investment.

I. Material Composition and Production Methods

To comprehend the impact of material quality on WPC wall panel prices, it is essential to first understand the composition and production methods of these panels.

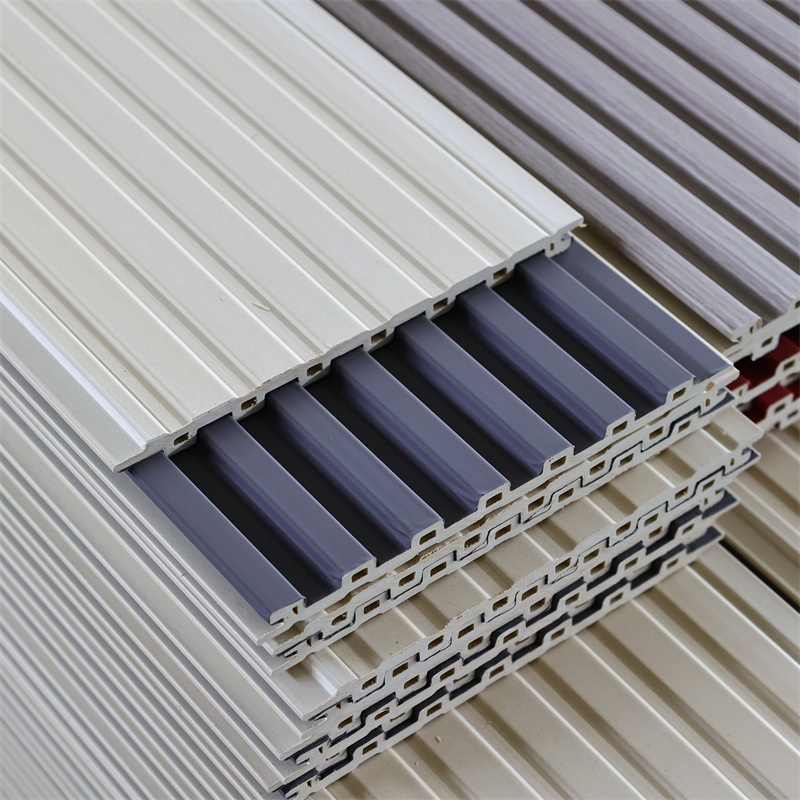

WPC wall panels are typically made from a blend of wood fibers or sawdust and thermoplastic materials, such as polyethylene, polypropylene, or polyvinyl chloride.

The ratio of wood fibers to plastic components significantly influences the panel’s performance, durability, and, consequently, its price.

1.1. Wood Fiber Content and Quality

The proportion and quality of wood fibers in the WPC mixture have a direct impact on the panel’s strength, stiffness, and overall appearance.

Higher wood fiber content often results in a more natural and authentic appearance, mimicking the look of traditional wooden panels.

However, as the wood content increases, the price may also rise due to the higher cost of sourcing and processing premium wood materials.

Conversely, panels with lower wood fiber content might be more cost-effective but could compromise on aesthetics and overall quality.

1.2. Thermoplastic Component Selection

The choice of thermoplastic materials can significantly affect the panel’s performance and cost.

Different plastics offer varying levels of durability, weather resistance, and environmental sustainability.

For instance, polyethylene-based WPC panels are more resistant to moisture and UV radiation, making them ideal for outdoor applications.

On the other hand, panels containing polypropylene may offer enhanced mechanical properties, but the cost of raw materials could be higher.

Manufacturers must strike a balance between cost and performance to offer competitive prices while meeting customer demands.

II. Quality Standards and Certifications

In the WPC wall panel industry, adherence to quality standards and certifications is essential to ensure the panels’ safety, longevity, and compliance with environmental regulations.

Manufacturers that invest in quality control processes and obtain certifications demonstrate their commitment to producing reliable and durable products.

However, such endeavors may also contribute to higher production costs, subsequently impacting the final product’s price.

2.1. Certifications for Sustainable Materials

WPC wall panels sourced from sustainably managed forests or recycled materials may carry certifications such as Forest Stewardship Council (FSC) or Leadership in Energy and Environmental Design (LEED).

These certifications add to the product’s market value and appeal to eco-conscious consumers.

Consequently, manufacturers may adjust the prices of certified WPC panels to reflect the additional effort and cost involved in obtaining and maintaining such certifications.

2.2. Quality Assurance Processes

To ensure consistent quality, some manufacturers implement stringent quality assurance processes during production.

These processes may involve material testing, moisture resistance checks, and adherence to international quality standards.

While such measures enhance product reliability, they can also lead to increased production costs, which may be reflected in the pricing of the final WPC wall panels.

III. Innovation and Technological Advancements

Technological advancements and innovations in WPC wall panel manufacturing can significantly influence material quality and, consequently, pricing.

New manufacturing techniques and improved materials may result in panels with enhanced properties, aesthetics, and durability, driving demand and potentially affecting prices.

3.1. Advanced Extrusion and Molding Techniques

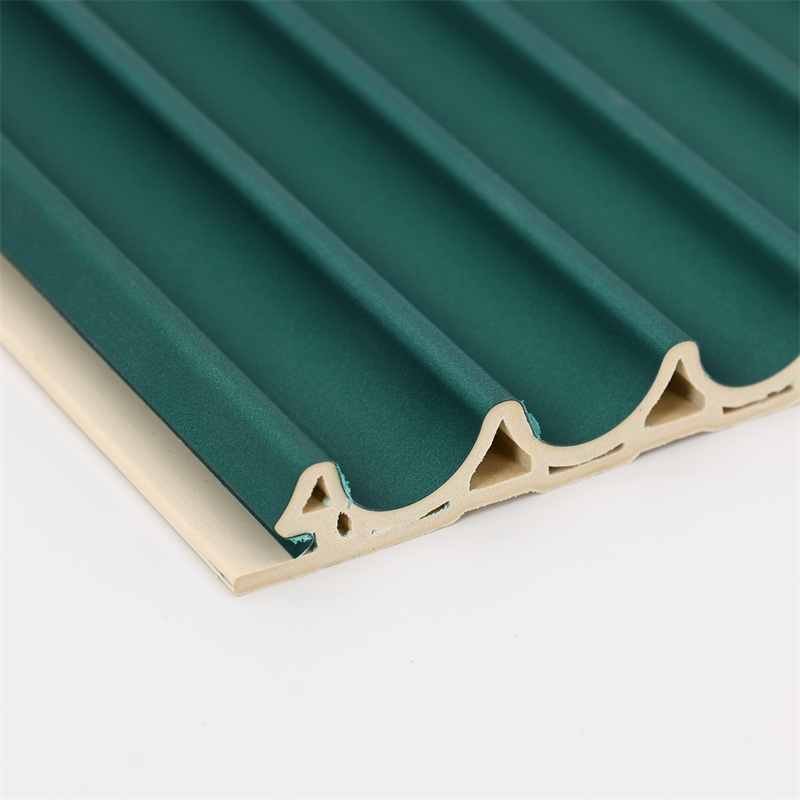

Incorporating cutting-edge extrusion and molding techniques can improve the bonding of wood fibers with thermoplastic materials, resulting in stronger and more visually appealing WPC wall panels.

Manufacturers employing these innovations may incur higher production costs, leading to higher-priced panels that boast improved performance and longevity.

3.2. Enhanced Protective Coatings

Developing superior protective coatings can enhance the panels’ resistance to fading, scratches, and other environmental factors.

Panels with enhanced coatings may command higher prices due to the added value they provide, ensuring a longer lifespan and reduced maintenance costs for consumers.

IV. Consumer Perception and Brand Reputation

Consumer perception and brand reputation play a significant role in shaping WPC wall panel prices.

Reputable brands that have established themselves as providers of high-quality and reliable products may charge a premium for their panels.

Consumers often associate brand reputation with product performance and durability, making them willing to pay more for a product they believe will meet their expectations.

4.1. Brand Recognition and Trust

Prominent brands that have gained recognition for their consistent quality and durability of WPC wall panels may price their products higher to capitalize on their reputation.

Consumers who value peace of mind and long-term satisfaction may be willing to invest in trusted brands, even if it means paying a premium.

4.2. Consumer Preferences and Demands

Consumer preferences also play a crucial role in determining WPC wall panel prices.

Panels featuring unique designs, colors, or textures that align with prevailing interior design trends may be in higher demand, leading to higher prices.

Similarly, customizations or specialty features catering to specific customer needs can also command higher price points.

The quality of materials used in WPC wall panels is a fundamental factor influencing their prices.

From the selection of wood fibers and thermoplastics to the adoption of innovative manufacturing techniques, every aspect impacts the panel’s performance, aesthetics, and overall value.

Additionally, adherence to quality standards, technological advancements, and brand reputation all contribute to the final pricing of WPC wall panels.

As consumers and industry professionals navigate the market, understanding the relationship between material quality and pricing empowers them to make informed decisions.

Balancing budget constraints with the desired level of quality and performance ensures that WPC wall panels selected

meet the needs and expectations of consumers while providing long-lasting value for their investments.