Wood Plastic Composite (WPC) wall panels have gained immense popularity in the construction and interior design industries due to their durability, eco-friendliness, and aesthetic appeal.

However, understanding the price factors that influence WPC wall panel costs is crucial for making informed decisions when purchasing or investing in these materials.

This ultimate guide aims to explore the various factors that determine WPC wall panel prices, empowering consumers and professionals alike with essential knowledge to navigate the market efficiently.

Material Composition and Quality

One of the primary price determinants for WPC wall panels is the material composition and its overall quality.

WPC panels are typically made from a blend of wood fibers or sawdust, thermoplastics, and additives.

The proportion and quality of these components significantly impact the performance and longevity of the panels.

- Wood Fiber Content: High-quality WPC wall panels generally contain a higher percentage of wood fibers, which enhances the panel’s strength and visual appeal. As a result, these panels tend to be more expensive than those with a lower wood fiber content.

- Thermoplastic Resin: The type and grade of thermoplastic resin used in the WPC mixture also influence the price. Premium-grade resins, such as PVC or HDPE, contribute to better weather resistance and overall stability, raising the cost of the panels.

- Additives: Certain additives, like UV stabilizers, colorants, and anti-microbial agents, may be included in WPC wall panels to enhance their performance and aesthetics. The presence of such additives can affect the final price.

Manufacturing Process and Technology

The manufacturing process and technology employed in producing WPC wall panels play a vital role in determining their price.

Advanced production techniques can result in higher-quality panels with superior features, but this may come at a premium cost.

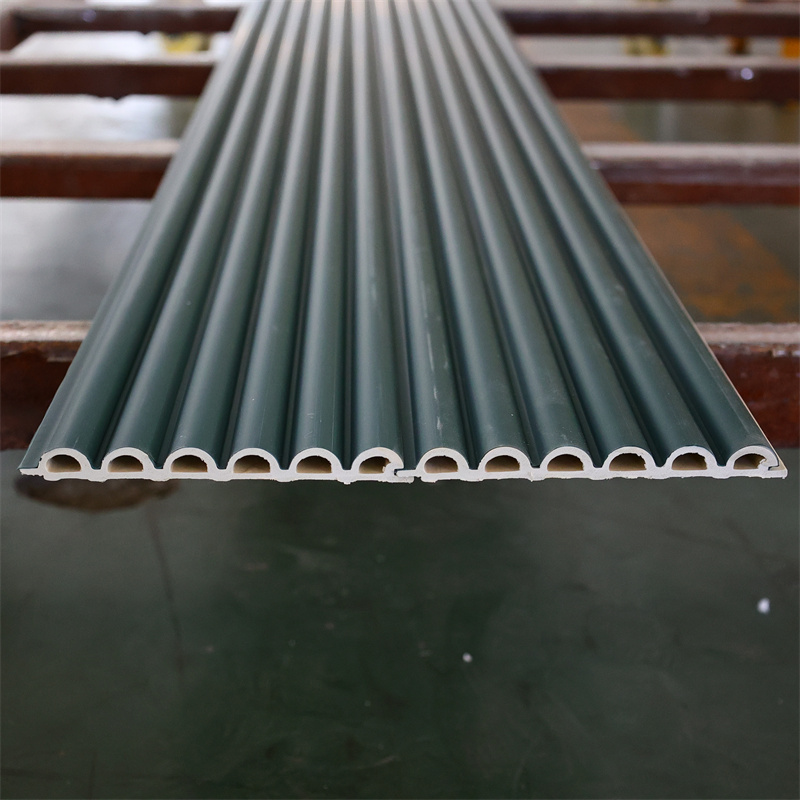

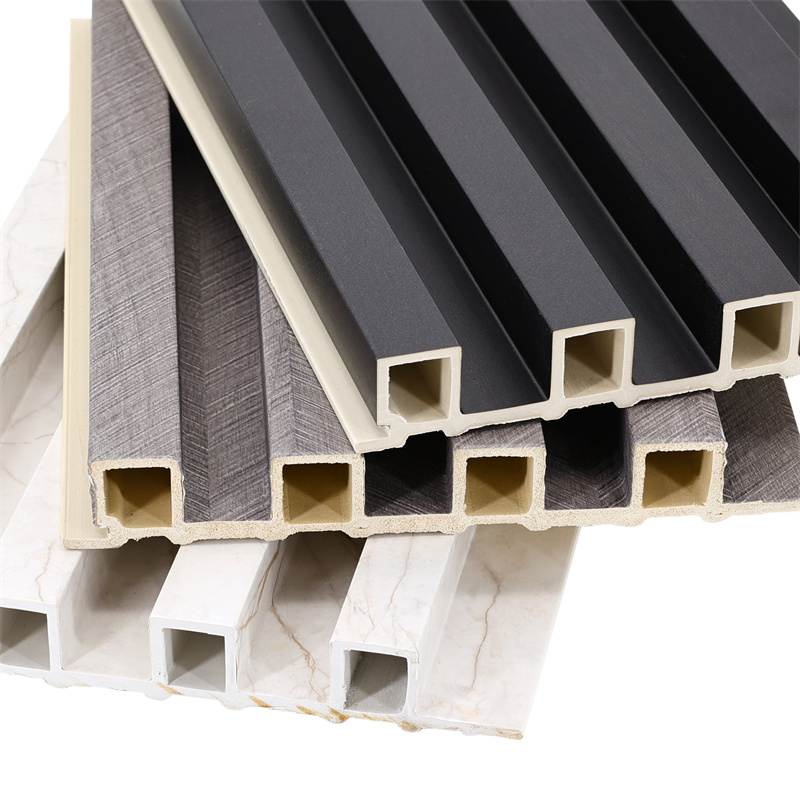

- Extrusion vs. Compression Molding: Extruded WPC panels are more common and often more cost-effective, as the process allows for high-volume production. On the other hand, compression molding can offer higher density and strength, but it tends to be more expensive due to its slower and more complex production process.

- Surface Treatments: Some WPC wall panels undergo additional surface treatments, such as embossing, brushing, or sanding, to mimic the appearance of natural wood grains. These extra manufacturing steps can increase the price, but they also contribute to a more realistic and appealing finish.

- Automation and Robotics: Manufacturers utilizing advanced automation and robotics in their production lines may produce WPC panels more efficiently, potentially leading to cost savings that can be passed on to consumers.

Size, Thickness, and Design Complexity

The physical attributes and design complexity of WPC wall panels have a direct impact on their pricing.

Panels with unique patterns, intricate designs, or customized dimensions often command higher prices due to the additional effort required in their production.

- Panel Size and Thickness: Larger panels with increased thickness generally cost more, as they require more raw materials and may involve specialized handling during manufacturing and transportation.

- Surface Texture and Finishes: Panels with elaborate textures and finishes, like 3D embossing or multi-tonal coloring, are likely to be more expensive due to the added labor and equipment needed for such artistic effects.

- Customization: Buyers seeking personalized designs or specific panel dimensions should expect higher costs, as custom manufacturing requires individual attention and may not benefit from economies of scale.

Market Demand and Supplier Competition

The basic principles of supply and demand play a crucial role in influencing WPC wall panel prices.

Fluctuations in market demand and the level of competition among suppliers can lead to price variations.

- Market Trends and Popularity: The demand for WPC wall panels can vary based on architectural trends, consumer preferences, and changing market dynamics. Panels in high demand may experience price increases, while those with lower demand may be more competitively priced.

- Supplier Competition: The number of manufacturers and suppliers in the market can influence pricing. Intense competition often leads to competitive pricing strategies to attract more customers, while limited competition may result in higher prices.

- Raw Material Costs: The price of the raw materials used in WPC wall panels, such as wood fibers and thermoplastic resins, can fluctuate based on market conditions. Suppliers may adjust their prices accordingly to accommodate these fluctuations.

In conclusion, understanding the various price factors that affect WPC wall panels empowers buyers to make well-informed decisions when choosing the right panels for their projects.

Material composition, manufacturing processes, panel attributes, and market dynamics all contribute to the final price of WPC wall panels.

By considering these factors and assessing individual needs and budget constraints,

consumers and professionals can strike the ideal balance between quality and cost-effectiveness in their WPC wall panel investments.

Whether for residential or commercial purposes, WPC wall panels offer a versatile and sustainable option for enhancing interior and exterior spaces,

with prices reflecting the quality, craftsmanship, and market dynamics of this innovative construction material.